After the rollout of CBAM regulations for exporters outside the EU, market players have become increasingly cautious of CBAM rules for their sectors. CBAM, introduced to prevent carbon leakage and encourage a level playing field for all players and exporters, affects hydrogen and fertiliser sectors too along with four other sectors. However, the monitoring, reporting and verification (MRV) rules apply differently for the hydrogen and fertiliser sector for their various sub-categories, production routes and production processes.

Fertiliser represents a significant amount of exported goods to the EU. As per the World Bank data, Belarus exports over 75% of fertilisers to the EU, followed by Georgia at 59%, Azerbaijan at 58%, 23% by Russia and other smaller players in the import-export business of fertilisers. As the stakes are so high, businesses are going to witness some significant transformation with respect to CBAM.

In this blog, we dive deep into the hydrogen and fertiliser sectors and give an outline of monitoring and reporting requirements as per changing activities and production processes.

CBAM rules for hydrogen

Hydrogen and the aggregated goods category are represented by CN code 2804 10 000. There are no relevant precursors for hydrogen. Hydrogen falls under the category of simple goods, as the raw materials and fuels used in its manufacture are considered to have zero embedded emissions. Direct and indirect embedded emissions need to be monitored, as per the methodology given by the implementing regulation outlined in section 6 of the CBAM guidance document. However, indirect emissions are only reported during the transition period and not during the definitive regime for hydrogen.

There are multiple monitoring and reporting requirements that are applicable to products only under the hydrogen sector in the context of CBAM. Here is a look at sector-specific reporting and monitoring requirements for hydrogen:

- Direct embedded emissions from the fuel combustion process in the hydrogen gas production process.

- Carbon dioxide emissions (direct) from the production of measurable heating and cooling consumed within the system boundary of production process.

- Direct carbon dioxide emissions from electrolysis

- Carbon dioxide emissions (direct) from emissions control activities

Hydrogen production routes and processes

Hydrogen is produced through various processes and routes. It can be produced from various feedstocks, including plastic wastes, but currently, it is derived mostly from fossil fuels. Hydrogen production units are typically integrated into larger industrial processes.

Steam reforming: The overall reaction in this production route is highly endothermic, and process heat is supplied by the combustion of natural gas or other gaseous fuel. All processes directly and indirectly linked to hydrogen production should be monitored. Indirect emissions resulting from electricity consumed by the production process should also be monitored.

Partial oxidation of hydrocarbons (gasification): In this category, Hydrogen is produced by the partial oxidation (gasification) of hydrocarbons, usually from heavy feedstocks like residual heavy oils, coal and waste plastics. This production route also does not have relevant precursors. Additionally, direct and indirect emissions must be monitored for this production route. Moreover, indirect emissions resulting from electricity consumed by the production process should also be monitored.

Electrolysis of water: Water electrolysis is a standalone and non-integrated production process that produces stream of hydrogen gas. Minimal direct emissions, and indirect emissions resulting from the electricity should be monitored. Moreover, there are no relevant precursors for this production process.

Chlor-alkali electrolysis: Hydrogen is produced as a by-product of the electrolysis of brine. There are three basic chloralkali process techniques: mercury cell, diaphragm cell and the membrane cell. All three cell techniques produce hydrogen, which is formed at the cell cathode and which leaves the cell at very high purity. Indirect and direct emissions must be monitored in this production process and route.

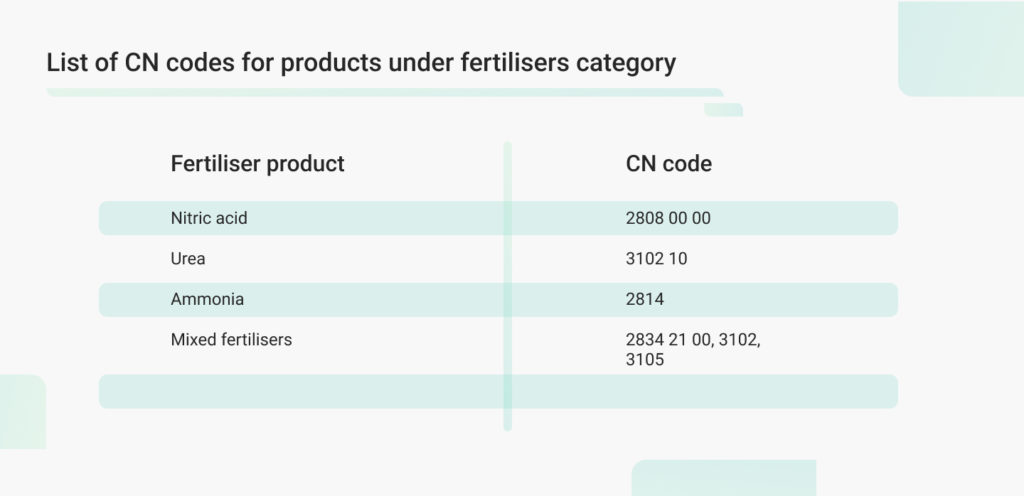

CBAM rules for fertilisers

The fertiliser industry sector has to account for both direct emissions and indirect emissions in the transitional period. Indirect emissions are to be reported separately. Emissions should be reported in metric tonnes CO2 equivalent (tCO2e) emissions per tonne of output. This figure should be calculated for the specific installation or production process in your country of origin. For the production of mixed fertiliser, not all precursors will apply in every case. Note in particular that in some instances, an aggregated goods category (mixed fertiliser itself) may be used as a precursor for its own category, depending on the final formulation of the mixed fertiliser product required.

Fertiliser production processes and routes

There are various production processes and routes for products under the fertilisers category of CBAM. They differ as per changing activities and different sub-products under fertiliser. Here is a look at it:

Haber-Bosch with steam reforming: Ammonia is synthesised from nitrogen and hydrogen via the Haber-Bosch process. Hydrogen for the process is obtained in this production route by steam reforming natural gas (or biogas) whilst nitrogen is obtained from the air. The overall reaction is highly endothermic and process heat is supplied by the combustion of natural gas or other gaseous fuel.

Haber-Bosch with gasification: With this production route, hydrogen is obtained by the gasification of hydrocarbons, typically from heavy feedstocks such as coal, heavy refinery fuels or other fossil feedstock. A synthesis gas containing hydrogen is produced, which has to be purified before it can be used for the next production step. Ammonia is then synthesised from the hydrogen produced and from nitrogen obtained from the air, at high temperature and pressure in the presence of a catalyst.

Nitric acid (and sulphonitric acids): Nitric acid is mostly produced via the oxidation of ammonia by Ostwald process. Ammonia is first oxidised in the presence of a catalyst to form nitrogen oxide, which is then further oxidised to nitrogen dioxide, followed by absorption in water in an absorption tower to form nitric acid. The reaction is exothermic and heat and power may be recovered to the process.

Urea production process: Urea is synthesised by reacting ammonia and carbon dioxide together at high pressure to form ammonium carbamate, which is then dehydrated to form urea. The Implementing Regulation (section 3 Annex II) defines the system boundaries for direct emissions monitoring for the urea production route, as encompassing:

Mixed fertilisers production process: A wide range of operations are included in the production of all kinds of nitrogen containing mixed fertilizers (especially ammonium salts and NP, NK and NPK), such as mixing, neutralisation40, particle formation (such as by granulation or prilling), irrespective of whether only physical mixing or chemical reactions take place.

Fertilisers: Specific monitoring requirements

Direct and indirect embedded emissions should be monitored in line with the methodology set out in the Implementing Regulation and outlined in section 6 of the guidance document. A look at some other relevant reporting requirements:

- Direct carbon dioxide emissions from the fuel combustion process from stationary plant only

- Direct carbon dioxide emissions resulting from the production of measurable heating and cooling that is consumed within the system boundaries

- Direct carbon dioxide emissions from emissions’ control methods and activities

Every non-EU exporter must be mindful of these relevant reporting requirements under the CBAM to reach the stage of being ready to implement the rules.

What is the way forward?

There are multiple complex production processes for hydrogen and fertiliser sectors under the CBAM. Every exporter sitting outside the EU has to fulfil all reporting requirements to be able to do business. Failure to comply with the CBAM could result in business setbacks and financial losses. However, the challenge can be fixed by ensuring that all the data is collected, measured and managed digitally with the help of TSC NetZero.

Due to diverse production processes in the hydrogen and fertiliser sectors, varied monitoring methods and reporting requirements are applied and designed as per sector-specific activities. Accurate embedded emissions data is a significant challenge, particularly with the newness of CBAM rules. TSC NetZero’s CBAM reporting software ensures precise data collection and accurate emissions calculations, facilitating timely reporting and avoiding penalties.